The cross-point screws used on Nikkor AI/AI-S lenses are typically JIS #0 and #00 and various slotted sizes, commonly 1.2mm for slotted grub screws (#000 cross-points do exist for some inbuilt lens hoods), but the older pre-AI lenses seem to have a wider range of slotted screw heads such as 1.2mm, 1.8mm and 3mm. This means that, as for many hobbies, there's a minimun bar of entry. For me, the following have been the options I've used to cover the various bases.

The Vessel 9900 #00 x 75mm and #0 x 100 mm / 150 mm plus a TD-51 1.2mm is good core set or one of the the Vessel sets: TD-56 (JIS #0, #00, slotted 0.9mm, 1.2mm, 1.8mm, 2.3mm) or TD-56s (JIS #0,#00, #000, #0000, slotted 0.7mm, 0.9mm) driver set includes a set of core drivers required for the majority of Nikkor AI/AI-S screws. The 9900 series are useful for their longer shafts for additional torque if required for stubborn/glued screws, particularly for helicoid screws on longer lenses.

An alternative is the Wera 2035/6A driver set that includes:

The key detail above is that the Wera Phlips PH #0 is JCIS #0 compatible - the slotted drivers have the same dimensions as the Vessel TD-51 equivalents.

To avoid confusion, it's important to point out that the Wera PH #0 driver in the above set conforms to a 2020 abandoned JCIS standard (the Japanese Camera Industry Standard). This can be seen as a "sub-standard" to the wider JIS B 1012 specification, as it specialized in size 0 and smaller screws (M1 to M2.6) commonly found in cameras and lenses.

Further to this, the JIS (Japanese Industrial Standard) is a much more wide-ranging standard. It includes the specific JIS B 1012 screw head and the corresponding JIS B 4633 screwdriver designed for use with those heads.

When a general or informal reference is made to a JIS driver, what is usually meant is a driver conforming to the JIS B 4633 standard. While this shorthand is technically simplistic, it identifies the tools suitable for properly engaging JIS B 1012 cross-point screw heads.

But theres more

Now that you've spent upwards of 30 GBP on some drivers, why not just use your Phillips driver thats been in your toolbox for years, especially if a JIS driver can be used on a Phillips screw head? Well, the TLDR: a JIS driver in Phillips head is ok, but NEVER a Phillips driver in a JIS head.

The key is the "point" and the wings of a Phillips driver - inserted into a JIS B 1012 screw the Phillips driver touches the bottom of the hole before the wings fully engages the screw's slots. This creates a "pivot point," causing the driver to spin like a top and damages/stripping the screw head.

The Wikipedia screw drives article states:

JIS B 1012 [screw head cross recess] was commonly found in Japanese made equipment, such as cameras and motorbikes. JIS fasteners superficially resemble a Phillips screw albeit one with narrower and more vertical slots. Compared to Phillips screws these differences give JIS fasteners less of a tendency to cam out. The bottom of the recess is flat, and the point of the driver has to be blunt. A Phillips screwdriver has the same 26.5 degree cone angle but because of the tapered slots will not seat fully, and will damage the screw if forced. A correctly sized JIS driver will engage at full depth into a Phillips or Pozidriv head screw slightly loosely, but without damage.

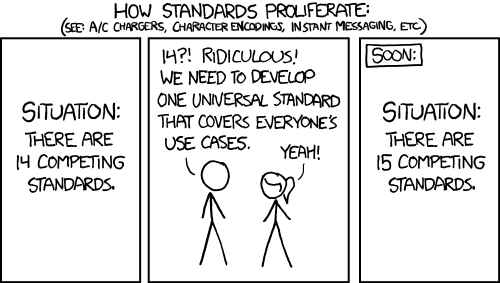

Researching the differences between Phillips vs JIS drivers (not the screws, that remained the same) and the various ISO (8764) vs JIS (B 4633) vs DIN (5260) standards and its harmonization/incorporation into ISO, will take you down a Coke vs Pepsi/Vi vs Emacs rabbit hole (tolerances of drivers and #0 and #00 pointiness problem) so I'll let reader explore independantly.

However given personal experience, when starting lens maintanence, of stripping (JIS) lens mount scerws with a Phillips driver I will follow common guidance of using JIS drivers on cross-point camera lens screws.

No comments:

Post a Comment